Blog

-

Transform Your UTV into a Powerful Riding Athletic Field Line Striper

If you’ve ever spent hours pushing a walk-behind field striper across multiple athletic fields, you already know the struggle: it’s time-consuming, physically demanding, and hard to keep consistent results when you’re tired halfway through the job. That’s why Newstripe developed the LineRider™ group of UTV mounted line stripers to give field maintenance teams, parks departments,

-

Industrial Waste Disposal Done Right: Safer, Smarter, and More Efficient Solutions

Industrial waste disposal isn’t simply about getting rid of used materials. For manufacturers, maintenance facilities, and industrial operations, it is a matter of safety, compliance, cost control, and environmental responsibility. When industrial waste disposal is handled incorrectly, it can lead to regulatory violations, workplace hazards, unnecessary disposal costs, and operational inefficiencies. Doing industrial waste disposal

-

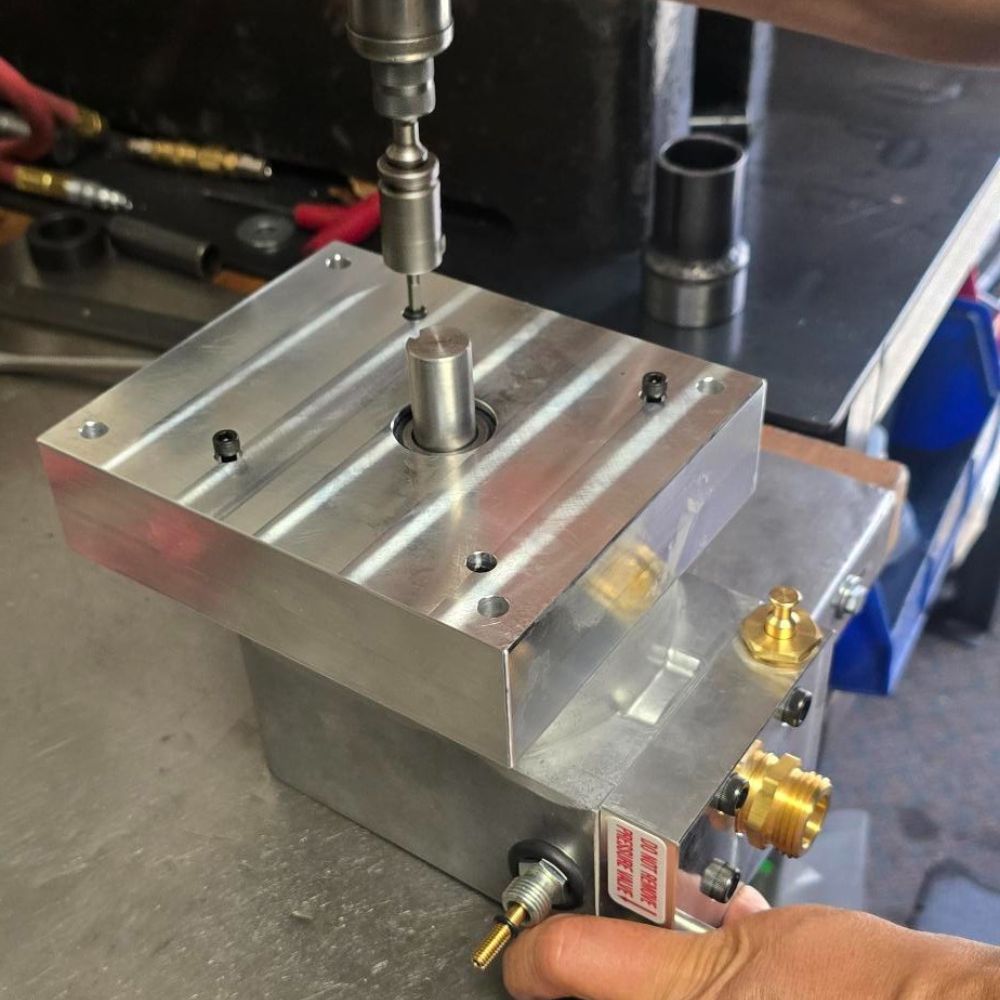

Keep Your Striper Running Smoothly with Newstripe’s Airless Pump Remanufacture Program

When your line striper’s pump starts losing pressure or struggles to keep up, you’re faced with a tough choice. You can replace your airless spray pump with a brand new one or you can explpre our Airless Pump Remanufacture Program where you swap out your worn pump for a “like new” remanufactured pump at a

-

AeroVent Safe2Vent Filters: A Smarter, Safer Way to Improve Aerosol Can Recycling

Aerosol can recycling has become an essential part of environmental compliance and sustainable business practices across manufacturing, automotive, industrial maintenance, and government facilities. But not all aerosol can disposal filters are equal in terms of managing volatile organic compounds (VOCs) and residual vapors released during processing. That’s where Newstripe’s patented AeroVent® Safe2Vent Filter makes a measurable

-

Simplify Aerosol Can Disposal with the AeroVent Crush 3X

Proper aerosol can disposal is essential for protecting the environment, staying compliant with regulations, and ensuring workplace safety. Aerosol cans are classified as hazardous waste because they are pressurized and often contain flammable or toxic substances. Simply throwing them in the trash can result in fines, safety hazards, or environmental damage. The recently launched AeroVent

-

The Perfect Combination for Parking Lot Striping

When it comes to parking lot striping, there’s no better way to achieve crisp, professional results than pairing the industrial‑grade Newstripe 4250 Airless Striping Machine with precision PolyTough handicap stencils and parking lot line stencils. This trifecta offers unmatched efficiency, compliance, and visual appeal to make it the ultimate choice for property managers, contractors, and maintenance

-

Athletic Field Maintenance: Tips, Tools & Best Practices

Maintaining safe, beautiful, and game-ready athletic fields is no small task. From baseball diamonds to soccer fields, proper athletic field maintenance ensures both player safety and an excellent game-day experience. Whether you’re responsible for a school district, local park, or professional facility, understanding how to care for your fields—and choosing the right equipment—makes all the

-

The Ultimate Airless Striping Machine for Versatility, Precision, and Value

When it comes to pavement marking and athletic field striping, choosing the right airless striping machine makes all the difference. For over four decades, Newstripe has been a trusted name in American-made striping and industrial equipment, and the 4250 Airless Striping Machine is one of our most cost-effective, high-performing solutions yet. Engineered for Performance and

-

PolyTough™ Stencils: Elevating Performance with a Lifetime Warranty

When it comes to pavement, floor, and field striping equipment, quality and durability are paramount. That’s where Newstripe’s PolyTough™ Stencils come into play, revolutionizing the industry with their exceptional performance and unbeatable lifetime warranty. In this article, we will dive into the world of 1/8″ PolyTough™ Stencils, highlighting their benefits, the wide range of stencil

-

How to Dispose of Aerosol Cans 101: Safe, Easy, and Compliant Solutions

When it comes to industrial waste, used aerosol cans are often overlooked — but improperly handling them can pose serious environmental and safety risks. Whether they’re empty or partially full knowing how to dispose of aerosol cans the right way is essential. In this guide, we’ll walk you through the basics of safe aerosol can