When it comes to line striping tasks, the right equipment makes all the difference. In recent years, the airless striping machine has garnered significant attention in the industry. But what exactly makes these machines superior to the conventional striping machine options? Here, we will delve deep into the advantages of airless striping machines and why they might just be the best choice for your project.

Efficiency at its Peak

One of the most commendable features of the airless striping machine is its efficiency. These machines typically require fewer passes to complete a striping job. This translates to reduced labor hours and faster project completion. When compared to conventional striping machines, airless models can complete projects in nearly half the time.

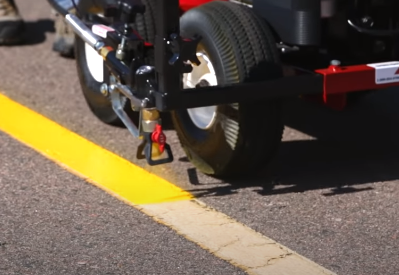

Consistent Paint Application

Uniformity is crucial when it comes to line striping. Airless technology ensures a consistent spray pattern. The result? Crisp, clean lines that are free from any variations in width or thickness.

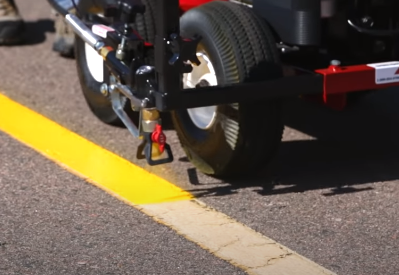

Airless Striping Machines Reduce Overspray

One significant advantage of the airless system is the notable reduction in overspray. Since there’s no air mixed with the paint, the delivery is more precise. This ensures that the paint goes exactly where it is intended, minimizing waste and increasing the overall quality of the job.

Better Paint Atomization

Airless striping machines deliver paint under high pressure, which leads to superior atomization. This means the paint particles are broken down into smaller droplets, providing a smoother finish. In contrast, conventional striping machines might not break down the paint as finely, which can lead to a grainier finish.

Versatility in Paint Choices

The airless striping machine is compatible with a broader range of paints, including those with higher viscosities. This versatility ensures that users can select the best paint for their specific project without worrying about machine compatibility.

Reduced Maintenance

With fewer components to worry about (such as compressors in traditional systems), airless machines typically require less maintenance. This can save on downtime and additional repair costs over the machine’s lifespan.

Greater Control and Precision

Due to their design, airless striping machines offer operators better control. With the adjustable pressure settings, users can cater to the operation of the machine to suit specific project requirements. This degree of precision is often challenging to achieve with a conventional striping machine.

Economic Benefits

While the initial investment might be higher for an airless system, the savings in time, paint, and maintenance can result in a more cost-effective solution in the long run. Considering the reduced overspray, there’s a significant saving on paint. Moreover, the decreased project time means potential savings on labor costs as well.

Environmentally Friendly

Given the precise application and reduced overspray, airless striping machines tend to be more environmentally friendly. There’s less wastage, which means fewer volatile organic compounds (VOCs) are released into the environment.

Adaptability to Various Projects

Whether it’s a parking lot, a sports court, or highway striping, airless striping machines are adaptable to a wide range of projects. Their efficiency and precision make them suitable for both large-scale and smaller tasks.

Final Thoughts

While both conventional and airless striping machines have their places in the industry, the airless variant undoubtedly brings a suite of benefits that can streamline operations and improve the quality of work. From the uniform paint application to the economic and environmental advantages, investing in an airless striping machine could be a game-changer for businesses and contractors in the line striping domain. Remember, the choice of equipment can significantly influence the quality, efficiency, and profitability of your striping project. By considering the benefits highlighted above, it becomes clear that the airless striping machine has carved a niche for itself, offering undeniable advantages over its conventional counterparts.