At Newstripe, we take immense pride in being a Colorado-based company dedicated to delivering top-notch pavement striping equipment to our local community. Based in Aurora, Colorado for the past four decades, we have specialized in manufacturing and distributing high-quality pavement striping equipment and supplies. With over 1,000 active customers throughout the state, we are committed to helping our customers enhance the appearance and safety of various surfaces in the Denver Metro area, Colorado Springs, Fort Collins, Boulder, Pueblo, and Grand Junction.

Our Commitment to Quality and Service

Newstripe is renowned for our innovative and reliable striping equipment. We offer a comprehensive range of products, including:

Pavement Striping Equipment

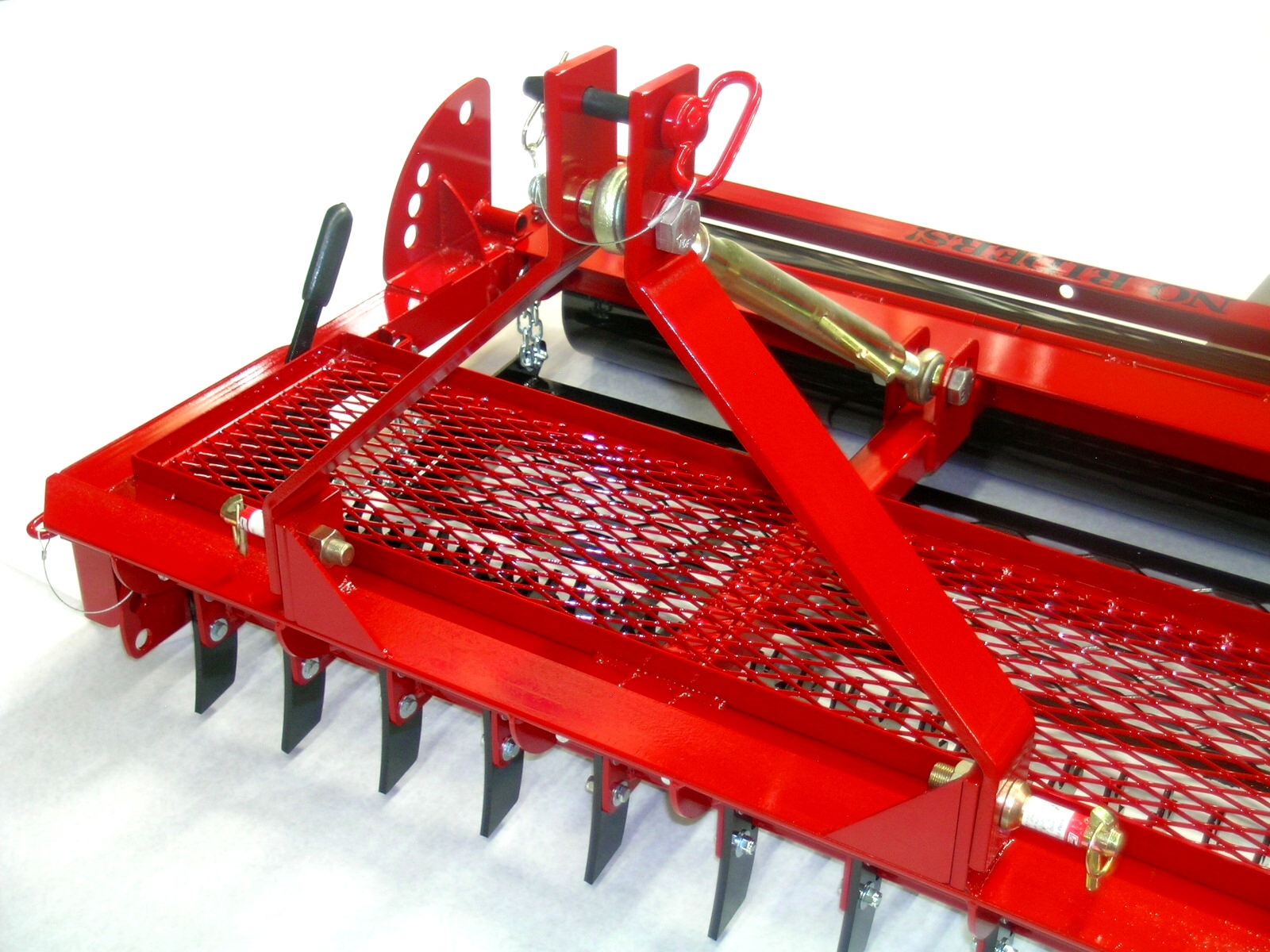

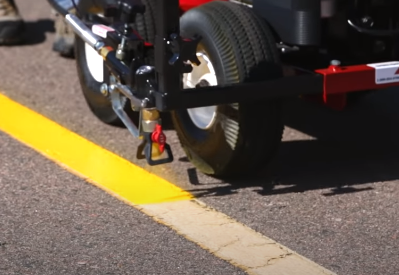

Our state-of-the-art pavement striping machines are designed to deliver precise and durable lines on parking lots, roads, pavement, and other paved surfaces. Whether you need a simple hand-push machine or a self-propelled system, we have the perfect equipment to meet your needs. Our equipment is engineered to handle the demands of various applications, ensuring that the lines remain clear and visible for an extended period.

Our offerings include:

- Hand-Push Stripers: Ideal for smaller projects, these machines are easy to maneuver and provide precise striping for parking lots and smaller roadways.

- Airless Striping Machines: These provide consistent, high-quality lines and are suitable for a wide range of applications, from small parking lots to large roadways.

- Battery-Operated Stripers: An eco-friendly option that combines efficiency with sustainability, perfect for environmentally-conscious customers.

Stencils & Accessories

In addition to stripers, we provide a wide variety of stencils and accessories to complement our striping equipment. Our PolyTough stencils are made from durable materials and are available in various sizes and designs, and all come with a Lifetime Warranty. Whether you need standard parking lot symbols or custom logos, our PolyTough stencils help you achieve consistent and precise results.

Our Stencils & Accessories include:

- Parking Lot Stencils: Standard symbols such as arrows, handicap symbols, and lettering to ensure your parking area is clearly marked.

- Custom Stencils: Tailored to meet your specific needs, from logos to custom messaging, enhancing your brand’s visibility.

- Line Striping Paint: High-quality, durable traffic striping paint in various colors to suit your project’s requirements.

- Replacement Parts and Maintenance Kits: Ensuring your equipment stays in top working condition, reducing downtime and maintaining efficiency.

Colorado Proud

As a company rooted in Colorado, we understand the unique needs of our local customers. Our team is dedicated to providing personalized service and support to ensure that our customers receive the best equipment possible. We are proud to be part of the Colorado business community and are committed to contributing to the safety and aesthetics of our local infrastructure.

Our deep connection to Colorado means we are familiar with the specific challenges and requirements in this region. We have the knowledge to offer solutions that meet our customers’ needs, taking into account weather and local regulations.

Serving the Entire State

Newstripe’s reach extends across the state of Colorado, ensuring that communities from the bustling Denver Metro area to the scenic beauty of Grand Junction benefit from our striping equipment. Our customers across Colorado trust us for our reliability, quality, and excellent customer service.

Join Our Growing Community

With over 1,000 active customers in Colorado and thousands more across the U.S., Newstripe has established itself as a leader in the pavement and field striping industry. Our clients include a diverse range of businesses, municipalities, schools, and organizations that rely on our products to maintain safe and attractive surfaces.

Why Choose Newstripe?

- Quality Products: Our equipment and accessories are manufactured to the highest standards, ensuring durability and performance.

- Local Expertise: Being based in Aurora, we have a deep understanding of the local market and can provide tailored equipment solutions.

- Customer Support: Our dedicated team is always ready to assist with any questions or concerns, offering expert advice and technical support.

The Newstripe Advantage

Choosing Newstripe means benefiting from:

- Innovative Technology: We continually invest in research and development to bring the latest striping technology to our customers, ensuring our equipment is at the cutting edge of the industry.

- Training and Resources: We offer comprehensive training and resources to ensure you can use our equipment to its full potential, maximizing efficiency and effectiveness.

- Sustainable Practices: Our commitment to the environment means we offer eco-friendly solutions without compromising on quality or performance.

- Local Partnerships: We work closely with local businesses and organizations, fostering strong relationships that benefit the Colorado community.

Contact Us

If you are looking for reliable and effective pavement striping equipment, look no further than Newstripe. Contact us today to learn more about our products and services or to schedule a consultation. Together, we can make Colorado’s surfaces safer and more visually appealing.